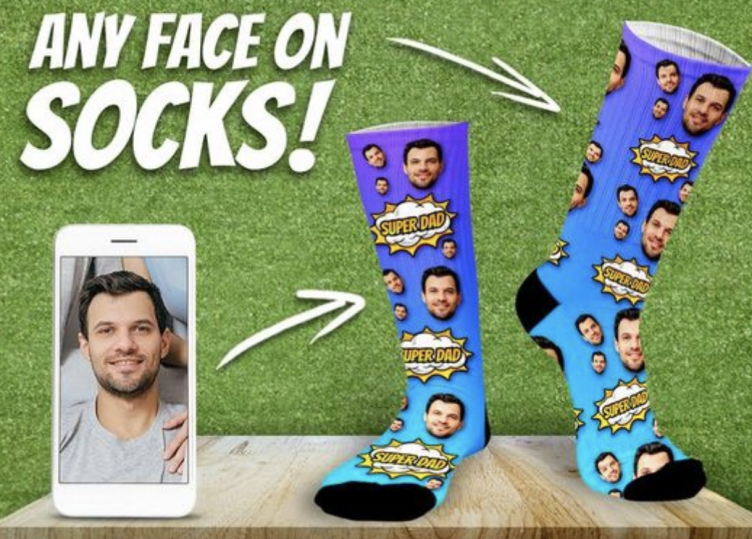

Socks are an important part of the closet and are related to comfort as well as fashion. Though they come in various fabrics, sizes, and patterns, a personalized touch can make you attractive to the crowd. The personalized touch-to-face socks or designed series can bring a dash of magic and reflect love when you gift them to your loved ones.

Custom socks don’t have any personalization limit and can be very creative. Face socks depict love and appreciation for the people and pets closest to you. Being a truly personalized product, they demonstrate your appreciation for distinct individuals in your life.

What are face socks?

Custom socks are increasingly becoming popular as gifts on different occasions, from Christmas to Valentine’s Day. They are also being used for incentives, promotional events, milestone birthdays, anniversaries, open houses, graduation, athletic camps, political campaigns, and even pet gifts. These are fun, stylish, and whimsical that allow you to add spark to daily life. You can buy Dad Socks, Pet Socks, or Holiday Custom Socks. They are a good option if you are in business as personalized socks with the logo of your company can act as a form of advertisement and promotion.

You can choose from standard socks, ankle socks, knee highs, or quarter socks for making face socks. Further, you need to have a good photo where all the face details are clearly visible but not too bright. These photos can be of pets, humans, cars, or even logos. You need to make sure that the whole face, along with both the ears, can be seen, so a head-on shot is preferred. The photo should have high clarity so that features don’t disappear if the photo shrinks. A maximum of four photos can be printed on face socks. At the same time, the photos should be separate as the face images will be cropped individually and placed separately on the socks.

The top brands for custom face socks are DivvyUp, FaceSocks, Pet Party, Sock Club, Rock ‘Em Socks, Bold socks and GiftLab. Some of them use sublimation transfer, while some others use 360-degree digital printing for making awesome custom socks.

How to make face socks?

There are two types by which custom face socks can be printed: sublimation transfer and 360-degree digital printing.

a) Sublimation transfer

An advanced method of printing on socks known as dye sublimation refers to the inkjet printing on transfer paper and using a heat press to transfer the print from the paper to the polyester fabric. After printing on transfer paper, the ink must be transferred onto a selected fabric at a high temperature and pressure to create socks. This process is called “solidifying” ink. Dye sublimation is best suited to synthetic materials, although it is not recommended for cotton or natural fibers socks. There are five steps involved in the process of sublimation transfer for printing face socks:

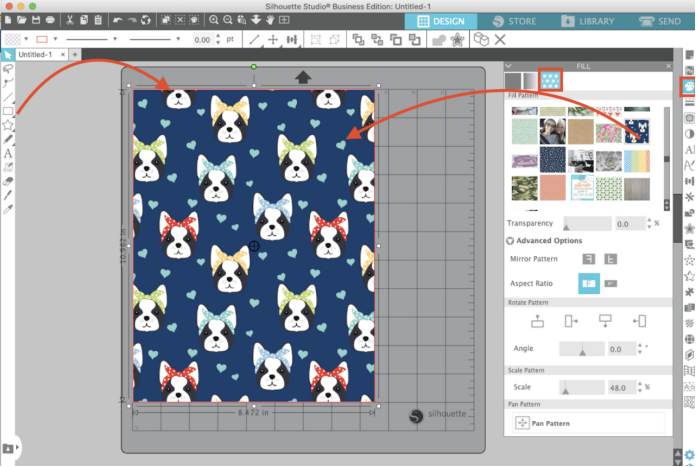

Step 1: Select the design

The design that you need to have on custom print socks is selected. You can either go for a pre-defined template or provide an image you need to have on socks. You can also choose the color or shade accordingly.

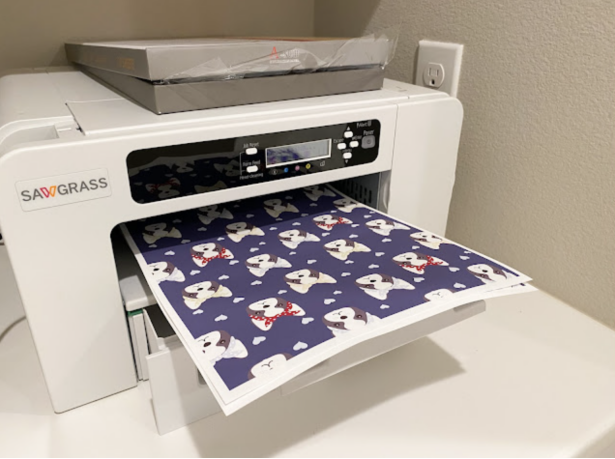

Step 2: Printing process

The design chosen is printed through sublimation transfer paper using a sublimation printer. Socks should be kept straight and stretched slightly at the top part to sublimate the ribbing. You can use a reusable jig for the same. When the socks are stretched, the fabric is more exposed to ink, giving a smooth print. The straightened position helps to sublimate the ink on the front and back sides of the socks. Slowly pulling the socks over the jig may take extra time to adjust, but it will assure that no press folds in the final design are left. At the same time, it has to be mentioned that the sublimation heat press will always have two sidelines.

After the socks are put over the jig, the press is heated up to 370 degrees by setting the timer to approximately 50-60 seconds. For a large printer, you can use tacky paper to keep the socks in place. In the case of sheet paper, you can use a repositionable spray adhesive. When the image gets printed, polish the image area with a spray or tape the socks to the transfer paper with clear heat tape. If flipping takes place simultaneously, the white edge may appear on the socks. To avoid it, slightly pull the colored edge from the first side to the second to cover the white area. Thus, it can be understood that there are three sub-steps: Flip, Switch, and Roll.

Step 4: Final step

After both sides are pressed, finished socks should be removed from the jig. Finally, you will be getting custom sublimated socks.

The problem with the sublimation process is that sometimes the image on the front and back of the socks might not be integrated or matched.

Step 3: Heat press process

b) 360-degree digital printing

Unlike dye sublimation, 360-degree printing may be used with all kinds of materials like cotton, polyester, wool, bamboo, etc. When printing on a sock, the ink needed and the method adopted is different for different materials. As the name suggests, wraparound printing employs a method of creating custom socks by stretching the material around a cylinder, allowing the printer to apply the chosen image, design, or pattern without the seams showing. If you’re looking for the most advanced printing of personalized socks, then 360-degree printing is probably the best option. This could be the finest option for you if you care about those things.

By printing one pair of designs simultaneously using 360-degree seamless printing, we can quickly switch between multiple designs in the software.

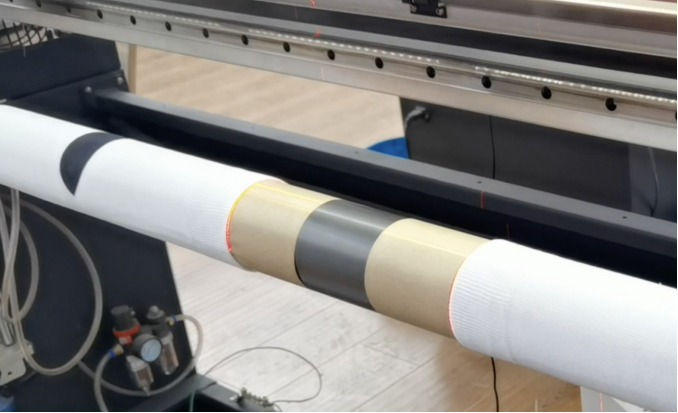

Step 1: Wrapping up the roller

A protective roller paper is used to keep the roller clean. As the name implies, it is properly wrapped around the roller to prevent it from becoming soiled. While a single protective paper can be replaced, it can be reused a number of times before being discarded. This paper makes it easier for socks to pull out over the printer.

Step 2: Printing process

The image(s) to be printed on the socks are uploaded on the software. They are re-sized to fit within the socks size to be printed perfectly. During the printing process, the socks are put on the roller and stretched flat. With the horizontal printing, the roller keeps turning. The turning helps to get the images printed on the socks smoothly.

Step 4: Heating process

In the heating process, the socks are removed from the roller. The toe part is hooked in a heat chamber set at 180 degrees Celsius for 3-4 minutes. The chamber presses the inks into the fabric, resulting in a vibrant image on the socks that lasted for a long time.

What does UNI Print offer?

Coming to face socks, UNI Print doesn’t offer face socks as retail for various reasons. The shipping fees from China to the US or other countries are at least 30-50$/time for each delivery of 1 pair or 2 pair orders. It is more than that purchased locally, which costs 15-25$. But we can print custom face socks for a business with minimum order quantity being 100 pairs as batch package delivery saves the shipping fees. If you like to start a custom face socks business, we are here to offer the required printing machines and equipment for custom face socks business locally. Our customer machine solutions also contribute to the development of brands. We can assist manufacturers in selling their products online because we have established relationships with prominent manufacturing organizations. Apart from that, we give outstanding customer service, machine setup assistance, and customer training.

Company advantage

Uniprint digital provide customer both socks printing service and Machine solutions.

Customer Service

Pls contact us from home page through Email/WhatsApp/Wechat, we will be glad to help answer all your questions regarding socks printing

Guarantee Policy

Free On line guidance for machine maintenance or installation is available, Machine warranty for 1year.(ink system no warranty)

Payment Terms

Uniprint digital provide the most convenience payment term, customer could choose T/T, Paypal, Western union.

Packing Standard

All the machines are well packed with strong wooden package with export standard quality.

Delivery

We provide Fob Shanghai as usually, by sea/air/train is available. With long-term cooperated shipping forwarder we can offer delivery to door service.

Post time: Dec-16-2021