High-Performance Fashion Textile Printing Solution

UniPrint Dye Sublimation Printer UP1804

Advantages of Sublimation Printing

●Print on Demand Technology

UniPrint High-Performance Dye Sublimation Printer is equipped with cutting-edge Print On Demand (POD) technology. As opposed to traditional printing methods, POD employs a “built-to-order” model where documents are only printed as they are ordered.

POD is less expensive, faster, and overall easier to implement - which means that you get to save a lot on all ends with our sublimation printing solutions.

●Wide Application

The UniPrint Sublimation Printer has a wide application! No matter what the niche of your business is, you can employ our printing solutions to elevate your work process.

Our application ranges from advertising, display, and home textile, right down to graphic apparel, customization gifts, and much more. Simply put: no matter what your business is, you can entrust our sublimation printing to help you as far as you can.

●Multiple Coloring Options

Our sublimation printing solutions come with no limits whatsoever! Want to print something colorful? The CMYK 4colors ink presents thousands of colors, so you don’t have to hold back on the aesthetic value of your fabric or other materials, and can get whatever colors you want right on paper.

Not only that but the print output with UniPrint Sublimation Printer operates at lightning speed. With 2PCS Original Epson head i3200, you can speed up to 40sqm/hr and with 15PCS Original Epson head i3200, you can speed up to 270sqm/hr.

UniPrint Dye Sublimation Printer UP1804 Advantage Features

Top-Notch Technology

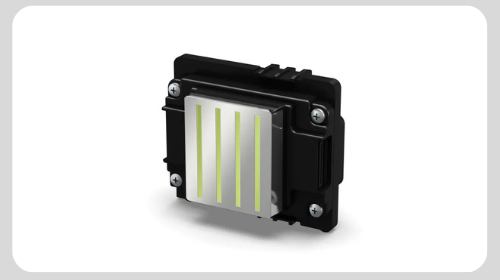

The UniPrint Sublimation Printer comes with the Epson I3200-A1 print head, TFP film piezoelectric technology, 3.5PL variable ink drop function. This means that our printing solutions allow accurate positioning of ink drop, give you richer and fuller colors, as well as make the overall printing effect way more exquisite.

Intelligent Sprinkler Cleaning

UniPrint Digital socks printer is equipped with two original Epson DX5 printheads that increase its speed and efficiency. Despite its high speed, it provides customized socks of exceptional quality by directly printing on socks. Epson’s unique micro piezoelectric printing technology controls the deformation of piezoelectric crystals. It precisely controls the size of ink droplets, ensuring excellent printing accuracy, with the smallest ink droplets up to 3.5PL.

Multiple Formatting Options

Tank towline of UniPrint digital Socks Printer has a silent drag chain that produces minimal noise during the printing process. The low noise of the machine results in lower vibrations, contributing to the longevity of the machine.

Continuous Ink Supply

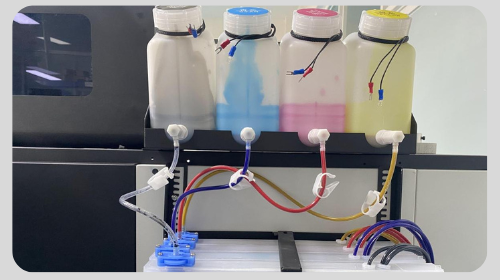

If you want to ensure that your business is on the right track, it is very important to ensure that you go for a printing option that is capable of providing an uninterrupted ink flow.

The UniPrint Sublimation Printer comes integrated with a Continuous Ink Supply System/CMYK Continuous Ink Supply. This allows for the secondary ink cartridges to steadily maintain liquid level stability, which in turn makes our printer the ultimate choice for bulk printing.

Video/ Parameter/Advantage in Components

Sublimaton Printing Solutions

With over 10 years of experience in the digital printing industry, UniPrint is the one-stop supplier for a variety of sublimation printing solutions. We gather the right equipment for you from different suppliers: sublimation printers, heat-press, rotary heaters, and laser cutters - to ensure that the unique printing needs of your business are rightly met.

At UniPrint, we value a customer-centric approach, and hence, our team of professional hardware and software personnel is focused on streamlining the printing process for your business as much as we can. We are aimed toward being there for you every step of the way, so you can rely on our customer representatives to help you 24/7.

| Model | UP 1800-4 | |

| Print head | Head type | EPSON I3200-A1 |

| Head qty | 4PCS | |

| Resolution | 720*1200dpi;720*2400dpi | |

| Automatic cleaning, automatic flash spray moisturizing function | ||

| Printing speed | 4pass | 80㎡/h |

| 6pass | 60㎡/h | |

| Printing ink | Colors | C M Y K |

| Max load | 3000ML/color | |

| Ink type | Sublimation Ink | |

| Printing Width | 1800mm | |

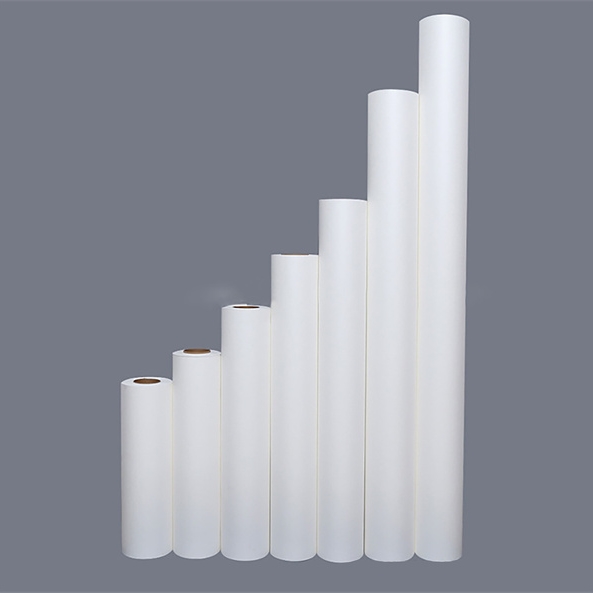

| Printing Media | Sublimation paper | |

| Media transfer | Cots transmission/automatic tension retracting system | |

| Drying | External intelligent Infrared heating and hot air fans integrated dryer | |

| Moisturizing mode | Fully sealed automatic moisturizing and cleaning | |

| RIP Software | Support Maintop6.1, PhotoPrint19, Default Maintop6.1 | |

| Image format | JPG, TIF, PDF, etc | |

| Computer configuration | The operating system | Win7 64bit / Win10 64bit |

| Hardware requirements | Hard disk: more than 500G (solid-state disk recommended), 8G operating memory, GRAPHICS card: ATI display 4G memory, CPU: I7 processor | |

| Transport interface | LAN | |

| Control display | LCD display and computer software panel operation | |

| The standard configuration | Intelligent drying system, liquid level alarm system | |

| The work environment | Humidity:35%~65% Temperature:18~30℃ | |

| The power demand | Voltage | AC 210-220V 50/60 HZ |

| Printing system | 200W standby, 1500W working | |

| Drying system | 4000W | |

| Size | Machine size | 3025*824*1476MM/250KG |

| Packing size | 3100*760*850MM/300KG | |

| Using epson I3200-A1 print head, TFP film piezoelectric technology + 2.5PL variable ink drop function, accurate positioning of ink drop, the image color level is richer and fuller, the printing effect is more exquisite |

| Intelligent sprinkler cleaning and moisturizing device, providing safe and convenient sprinkler cleaning and maintenance functions, more convenient operation and maintenance |

| Gigabit network data transmission port, meet the requirements of digital printing hd picture output stability and transmission speed |

| High-quality imported accessories: THK mute guide rail, Japan NSK bearing, Germany igus ink chain system, Leadshine servo brushless integrated motor, etc., smooth movement, longer life, tell the movement can effectively reduce the resistance and noise in the operation of ink car |

| Anti-collision trolley frame: can adjust nozzle height freely according to different printing consumables, widely used, easy to adjust, increase anti-collision device at both ends, give nozzle more comprehensive safety protection. |

| Expansion shaft type retracting and unwinding system: adjust air pressure automatically. Make the force uniform, making the paper more smooth. It has the characteristics of large load-bearing weight, long service life, even loading and unloading force, short inflating and deflating operation time, etc |

| The unique swing bar in the winding and unwinding system ensures that the paper is stressed evenly throughout the printing process, and the paper is smooth and tight, avoiding the tightening. |

| Intelligent induction drying system: intelligent infrared fan can be used for heating and blowing at the same time, realizing the humanized design of automatic closing of the printing stop fan to ensure that the picture is not damaged. |

Related Products

UniPrint Offer you different head configuration sublimation printer such as UP1802(2printheads). UP1804(4printheads). UP1808(8printheads). UP2015(15printheads) Related equipments like rotary heater, Laser cutter, Consumable supplies like sublimation inks, sublimation paper etc.

UniPrint UP 1802 is another variant of a sublimation printer. It supports 2 print heads and can achieve a printing speed of 40㎡/h (4 Pass). The maximum printing width you can achieve using this printer is 1800mm. You also get an excellent print resolution of 1440x2880dpi.

Featuring 8 pieces of print heads, the UniPrint UP 1808 sublimation printer gives you a maximum printing speed of 320㎡/h with 1 pass and 160㎡/h with 2 passes. The printer is designed to give you top-notch sublimation printing as it has an integrated dryer and intelligent infrared heating for quick drying

UP 2015 sublimation printer is suitable for businesses that take sublimation printing orders in bulk. The printer comes with 15 print heads and gives a print resolution of 1440x2880dpi. You get a super printing speed of 550㎡/h with single-pass and 270㎡/h with double-pass. Furthermore, you get a maximum print width of 2000mm.

UniPrint rotary heater helps you with the heat transfer process. It is a vital step in sublimation printing. The heat press machine allows you to transfer the print pattern from sublimation paper to polyester-based textiles. The heating and pressing ensure that the ink has dissolved properly. You can use our rotary heater for both cutting pieces and roll-to-roll fabric.

UniPrint Big visual laser cutting machine automates the process of cutting out dye sublimation printed pieces of fabric or textile both quickly and accurately, automatically compensating for any distortions or stretches that occur in unstable or stretchy textiles - exactly the type of fabrics that are used in sportswear.

UniPrint also provides premium quality UV Ink to help you get superior UV printing. We have CMYK, CMYK+ White, and CMYK+ White+ Varnish ink configuration. The CMYK ink enables you to print on all types of white background color substrates. CMYK+ White is suitable for dark background material. And if you want glossy layer UV printing, you can go for CMYK+ White+ Varnish ink configuration.

UniPrint offer sublimation transfer paper from low gsm 30gsm to high gsm like 120gsm. in different format. the largest can be supported in 3.2m width. UniPrint sublimation transfer paper has higher transfer rate reach to 95%. paper is with uniform coating, fast ink absorption, fast drying, small paper deformation

About UniPrint Digital

UniPrint offers an all-encompassing printing solution, from sublimation printers and heat presses to rotary heaters, laser cutters, and much more. Our highly experienced team of hardware and software experts and R & D professionals ensures the highest quality across all our products and services.

Here’s how we stand out from other brands

● Free sampling: we offer free existing and custom samples to customers before their purchase and free spare parts along with every purchase of our simulation printer.

● We offer FOB, CIF sea, and door-to-door service to facilitate customers no matter where they are.

● Round-the-clock customer support to ensure customer satisfaction, anywhere, anytime!

Machine Solutions

UniPrint offer high-quality printing equipment for your printing needs

Sampling Service

Free samples of custom designs so you can test our products commitment-free!

Worldwide Delivery

International delivery options with travel-safe packaging of products

Machine Warranty

UniPrint offers a machine warranty of 12months based on the installation

Showcase

Frequently Asked Questions

Sublimation printing is one of the most popular printing processes. It involves the transfer of a design from the sublimation paper onto other materials such as fabric sheets, using heat and pressure simultaneously. The actual process entails changing the solid particles of ink into a gaseous state, which then leaves a print wherever you want it to. Due to this, you usually have to use it with a heat press machine or a rotary heater.

As a whole, sublimation printing is a relatively newer method. However, it is quickly picking up pace in terms of popularity, considering how it takes less time, is more cost-effective, and is easy enough for people to execute even at home. Hence, it is a great option for businesses! It is very profitable, helps businesses stay within budget and save money, and of course, creates beautiful aesthetically pleasing products.

Sublimation printing is a very easy process and does not require a lot of effort from your side. As long as you get yourself the right equipment and familiarise yourself with the ins and outs of sublimation printing properly, you are well-sorted and can easily do it yourself!

In this regard, the first thing we suggest you do is to get a sublimation printer and a heat press machine/a rotary heater. This is the main equipment you need to be able to properly execute the sublimation printing process. Other than this, you will also need sublimation ink, transfer paper, and polyester fabric.

Once you have gathered all the necessary equipment, you can proceed to print your design onto transfer paper. This is essentially the part of the process where you employ a sublimation printer.

After printing the design on the transfer paper, you should then use a heat press machine or a rotary heater to transfer the design onto fabric. This will usually be fully polyester fabric or a high polyester content fabric that is white in color. You can use other colors as well, but sublimation printing goes the best with white fabric in terms of the printing effect.

All sorts of products!

That’s probably one of the best things about sublimation printing: it can be used to personalize many kinds of products. The most prominent kinds of products that can be elevated through sublimation printing are the following: sports garments, beanies, shirts, pants, and socks.

However, you can even use sublimation printing for items that are NOT clothing, such as mugs, phone covers, ceramic plates, and whatnot? The list is a little long, but these products should give you an idea of the kind of stuff that is covered

Fully polyester fabric or high content polyester fabric only! Polyester is the only fabric that will sustain your design. If you print something on cotton or other similar fabrics, it’s not going to work well because the print is simply going to wash off.

Refer to the second question on this list for more detailed information on the equipment you need.

However, to start off, here’s a small list of all the supplies you may need for sublimation. Remember: this list is by no means exhaustive and may vary depending on the needs of your project.

● Sublimation printer

● Heat press machine/rotary heater

● Laser cutter

● Sublimation ink

● Sublimation transfer paper

● Protective paper

No! Because the design is embedded into the substrate/fabric, it cannot be washed away easily. In fact, it cannot be cracked.

However, you do need to make sure that the fabric you are using is polyester and not cotton fabric because sublimation printing doesn’t do well with any other kind of fabric than polyester.

Generally, sublimation printing is only done on white or light color fabrics. Dark colors like black cannot really work well with sublimation printers. This is because most sublimation printers, including UniPrint Sublimation Printer, use CMYK technology. There is no white layer in the designs using this technology, and therefore, they cannot be used on dark fabrics such as black or any other dark color.

Because of CMYK technology. However, technically, white is not the only color you can work with. You can opt for other light colors, whether it is pastel colors or lighter shades of other colors.

Essentially, as long as you can make sure that the CMYK technology is compatible with a certain color, you can use it.

This is a great question! Why should you use sublimation printing?

1. It is simple, fast, and cost-effective.

Running a business is no easy task, and if there is a printing process that will help you save not only money but also time and effort, why shouldn’t you go for it? Sublimation printing is a cost-effective solution to producing personalized, aesthetically pleasing products.

2. Unlimited colors.

You can print any color (except white) onto your fabric or substrate! What better way to elevate your products than to flaunt different hues of pink, purple, and blue? With sublimation printing, your product is your canvas and you can paint it with whatever colors you deem appealing. The choice is completely yours!

3. Wide application.

Another great thing about sublimation is that it can cater to multiple applications. If you have a business that provides rigid objects like cups, mugs, ceramic tiles, phone case covers, wallets, or flip flops, you can massively benefit from sublimation printing. However, if you run a clothing business and want to use sublimation printing for products such as sports garments, flags, and backlight cloth - basically all sorts of fabrics that are made of high content polyester.

4. Bulk production.

If you are looking for a printing process that fits low MOQ orders and bulk production orders, then sublimation printing is the best possible option. The UniPrint Sublimation Printer, for example, employs Print-on-Demand (POD) technology, which means that there is no minimum on printing: you print precisely as much as you need, nothing less, nothing more.

Unfortunately, it is not all sunshine and rainbows when it comes to sublimation printing. However, to make an informed choice, it is equally important for you to know the disadvantages of sublimation printing as it is for you to know the advantages! So, let’s have a look:

1) Only polyester.

Polyester is the only fabric that does well with sublimation printing. This really limits your options of products as a business. Because cotton and other kinds of fabric can’t sustain sublimation, you have to ensure that all the products you are putting through the sublimation printing process are polyester. Essentially, all your products should be either fully polyester or have a high content of polyester within them.

2) Polyester coating.

If you are not exclusively working with fabric and want to do sublimation for non-textile products, then you can only do so on products that have a special polyester coating. Any object that does not have this coating will not be able to take the sublimation process and hence cannot bear your design. As you can probably tell, this is a major setback for a lot of businesses as it gravely limits the kind of products they can offer their customers.

3) Only white/light background.

Sublimation can only be done on white, or other light-colored backgrounds. Again, this is a limitation that can hold you back as a business, considering the limitation it puts on the color palette that you offer.

4) Fading away.

Although sublimation rarely fades away, if your product is excessively exposed to sunlight there is a very good chance that it will fade away and hence, might decrease the credibility of your business (in case your purchasers are not warned of this in advance.

This is tricky. The temperature used for sublimation typically depends on what kind of substrate is used in the process. Although it’s usually adjusted accordingly, a temperature of 360°-400°F is recommended. This temperature needs to be maintained for 45-60 seconds. This again will need to be adjusted according to the testing result. It’s important to conduct thorough research and find a suitable time and temperature to sublimate your products, or the results could be disastrous!

Good question! The short answer is that it varies. This is because we have a few different models of sublimation printers. For example, the 2printhead model speeds up to 40sqm per hour! On the other hand, the 15heads model speeds up to 270sqm per hour.

The price of sublimation ink comes down to $15/liter on average and a 1-liter print is approximately 100 - 140 square meters for mixture colors. As you can tell, this makes it a lot cheaper than traditional methods of manufacturing and printer, and hence a better option for businesses that are aiming to save money.

This is another tricky one! It largely depends on your designs. A bigger, more complex design will use up more sublimation ink as opposed to smaller, simpler designs. But just to give you an estimate; 1 liter of sublimation ink can print for up to 100sqm.

The UniPrint Sublimation Printer comes with a warranty of 1 year against the setup of the machine. When it comes to spare parts related to the ink system of the printer there's no warranty as of yet!

But we’re not the only ones, this is the printing machine industry rule, as there are too many varying and unpredictable factors that can cause the printhead damage. For example, there are numerous mistakes that can occur through the human operation of the printers. Another issue seen with printers or electronics, in general, is the short circuit of electricity. But worry not! UniPrint is unique in that our customers would have lifetime customer after-sales service! Our team is always ready to assist and advise you whenever you face any issue related to your Sublimation Printer.

The easiest answer is that it depends on how well you use it; as long as you maintain it, it can last a considerably long time. The UniPrint Sublimation Printers use the Original Epson printhead i3200-A1. The Original Epson printhead i3200-A1It provides high productivity and high image quality with 600dpi high-density resolution. With excellent maintenance, the print head’s life span is nearly 24 months.

Yes, you can! If you want to ensure that you are investing your money in the right place, you can try us out before you actually commit. This will allow you to not only see if our claims are accurate, but it will also give you a chance to ensure whether sublimation is the right printing solution for your business needs.

For a sublimated sample, please contact us by email; sales@uniprintcn.com. If you have a specific design in mind or have the original artwork, please share that as well. We would love to prove ourselves to you before you commit.

We believe in being as eco-friendly as possible with our printers. Sublimation inks are water-based, making them 100% eco-friendly and safe for the environment. Moreover, sublimation doesn’t require as much water as other transfer-dye methods, making the process itself environmentally conscious. Natural resource conservation is important!

This is the same as the equipment that you would need for sublimation in general: and that’s probably the best part about this process. As a business, you don’t have to go over and beyond to ensure that you are executing the sublimation printing process perfectly. You don’t need much to begin a sublimation business right from your home! If you’re confused about where to start looking, don’t worry, we’ve got you!

Here’s a list of all the basic equipment you’ll need to start your own sublimation business.

● Sublimation Printer

● Sublimation Ink

● Transfer Paper

● Heat press or Rotary heater

● Cutter or Laser