Sublimation is a very popular option, because it’s a very simple operation that provides high output. Especially when it comes to sports garments, especially socks. For sublimation, all you need is a sublimation printer and a heat press or a rotary heater so you can start bulk-producing socks with many different designs.

But there’s another option to consider when it comes to printing on socks, which brings us to DTG socks. DTG printing, also known as direct to garment printing, digital printing, or 360 printing, is another great method to print on textiles and it’s commonly used for ready-made garments such as t-shirts and socks.

Today, we want to go through both processes of printing so you can determine which one you like best. So, let’s understand the procedure for both sublimation socks and DTG socks!

Sublimation Socks

The sublimation process for socks is very simple and easy to do. All you have to do is find the design you want to use, print it on paper, cut the paper to fit the socks, and use a heat press to transfer the print onto the socks on each side. For this process, you’ll need socks, a sublimation printer, sublimation paper, sock jigs, and a 15 by 15” heat press. The sock jigs will help you stretch the socks ever so slightly during the sublimation process and it will also keep the socks flat.

If you want full-patterned sublimation socks, you’ll have to print your design on full sublimation sheets. You want to make sure the page size matches the maximum printer size. Once the design is ready, you’ll need to print 4 sheets for a set of socks. Then, all you have to do is use your sublimation printer and that’s it!

DTG Socks

The direct to garment printing process is not too different, but it’s a bit easier and less time-consuming than sublimation. You need the design, which is printed directly on the socks, and then the print is curated with heating, and that’s it!

To make DTG socks, you need a digital socks printer, with which you can print any design on blank polyester socks. You also need a heater, which must be customized, and you only have to hook the socks on the toe part and the machine will turn the socks into the heater. This will take up to 4 minutes at 180 degrees Celsius.

If you want to print on cotton, wool, nylon, or other materials, you will need pretreatment. This is also known as the coating process, where the socks will be soaked in a coating liquid before the printing process to process the design.

Here’s a PHOTO comparing sublimation socks and DTG socks:

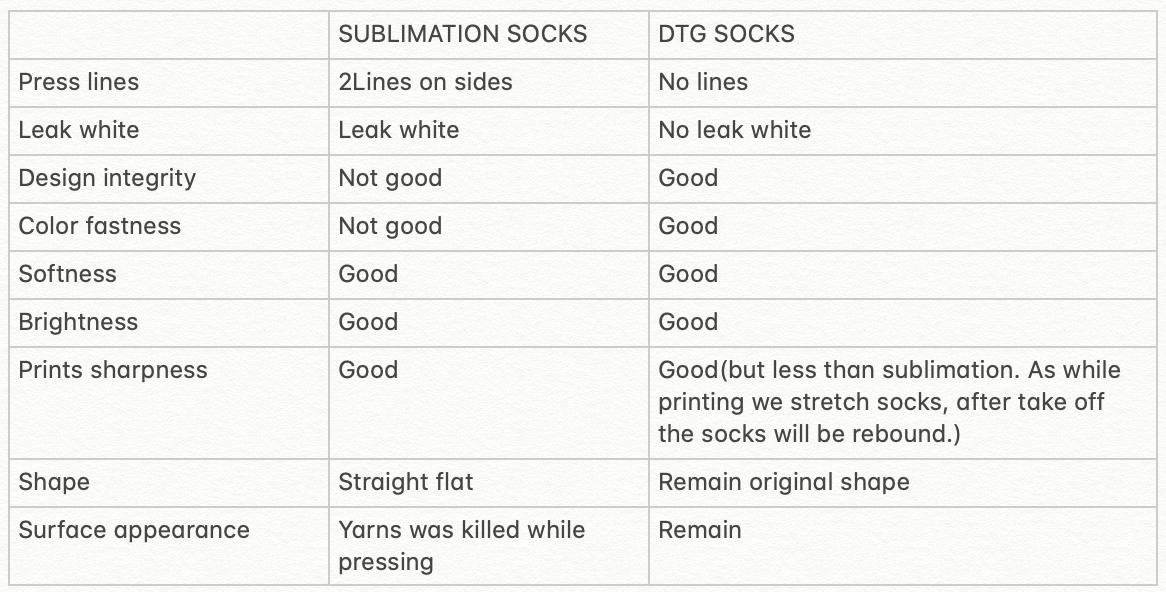

And here’s a table explaining the differences between the two kinds of finishes:

Personally, we prefer DTG socks and it’s what we offer to our customers! This process is a lot more versatile because it allows us to print on different materials, including cotton, polyester, bamboo, wool, etc., which is why we provide such a great variety of socks. Check out videos in Uni print Channel . Also, let us know if you prefer sublimated or DTG socks!

Post time: May-25-2021